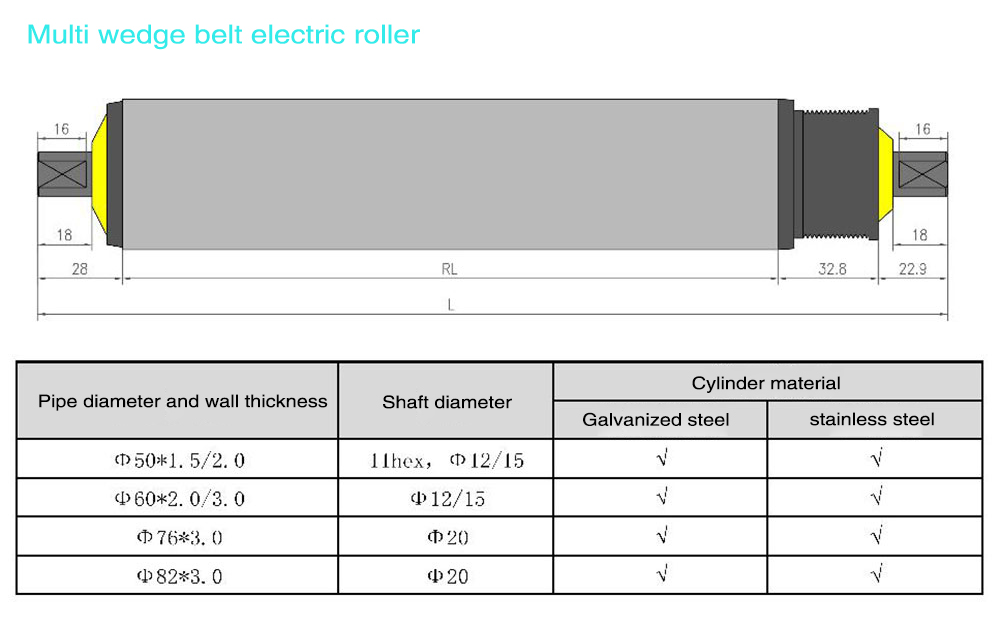

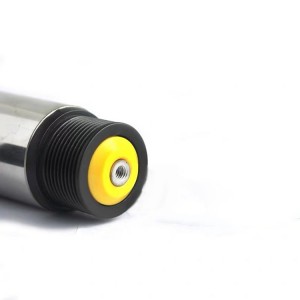

Poly-vee Conveyor Roller

1.Quiet operation, higher transport efficiency

2.9 V-grooves, more options of PJ poly-Vee belt

3.Application for middle&high speed, light&middle duty

The application of power conveying drum machine was first applied abroad, and its development is also relatively fast. With the development and improvement of computer technology, communication technology, control technology and detection technology, as well as their universal application, the development of power roller conveyor also ushers in a diversified era. There are many types of power roller conveyor, such as tubular belt power roller conveyor, high inclination belt conveyor, space turning belt conveyor and so on. Although the development lags behind, it has not lagged behind. The research and development of new technologies and new products has achieved considerable results. For example, the research and development of telescopic belt conveyor, the research and development of large angle and long distance belt conveyor and the use of programmable controller play a great role in promoting and guiding the development of power roller conveyor technology.

For the power roller conveyor, the control system of underground power roller conveyor is mostly used to monitor the rotation. The control system of underground power roller conveyor is an ideal automatic system applied to mineral mining and transportation. Combined with modern information communication, it not only ensures the smooth progress of underground operation, but also increases production efficiency and realizes good economic management benefits. At the same time, the use of mechanical automatic control also effectively ensures the construction, reduces the intensity of production and management as much as possible, and has good reliability.