DC brushless electric roller

-

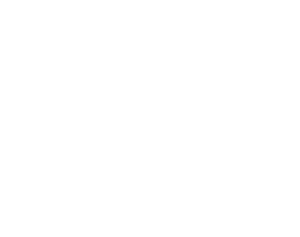

BLD DC brushless electric roller

This type of drum motor can be installed in limited space and meet the torque requirement. Using alloy steel grinded gears and planetary transmission structure, it is reliable,free of maintenance and oil-renewing, space-saving. It can be use in many fields:

Supermarket cashier

Packaging machinery Belt conveyor

Belt conveyor lineBL50 Characteristics Of Drum Motor

Drum Shell

Material of standard drum shell is mild steel • Food garde shell is 304 stainless steel • Standard cylinder rolling mill gear slip flower – gear • High alloy steel precision, ensures low noise transmission when the • Planetary gear transmission -

Double Groove O-belt Pulley Roller

1. The O-belt pulley is located the end of the roller which separates the drive area and the conveying area avoiding interference between the O-belt and the conveyed goods.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. Because there is no grooving of the tube, the tube will not have any distortion and the roller will run more smoothly.

5. Standard configuration with anti-static design surface impedance≤106Ω。

6. Temperature range: -5℃ ~ +40℃. Please contact us if humidity out of this scope. -

Poly-vee Conveyor Roller

1. The poly-vee pulley is located at the end of the roller which separates the drive area and the conveying area making the conveying smooth, high speed and low noise.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. ISO9982 PJ series poly-vee. Total of 9 grooves at 2.34mm pitch.

5. Various PJ belt lengths available to suit different pitch of rollers.

6. Suitable for the high speed applications. Maximum speed varies with roller length and diameter. Maximum speed up to 2~3m/s.

7. Standard configuration with anti-static design surface impedance≤106Ω。

8. Temperature range: -5℃ ~ +40℃.

Please contact us if humidity out of this scope. -

Double Grooved O-belt Conveyor

1. Compared with chain drive, the O-belt drive has the advantages of low noise and high speed. It is widely used for light/medium duty carton

conveying.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. The position of the grooves can be customized.

5. Standard configuration with anti-static design surface impedance≤106Ω。

6. Temperature range: -5℃ ~ +40℃.

Please contact us if humidity out of this scope. -

Timing belt pulley conveyor roller

1. Compact structure, tension free, simple design.

2. T5 tooth profile suitable for roller conveying, higher universality.

3. Accurate positioning, combine with MDR can match the application of transplant section.

4. Combine with PU Timing belt can match the application of clean room and other harsh environment.

5. Self-lubricating and maintenance-free. -

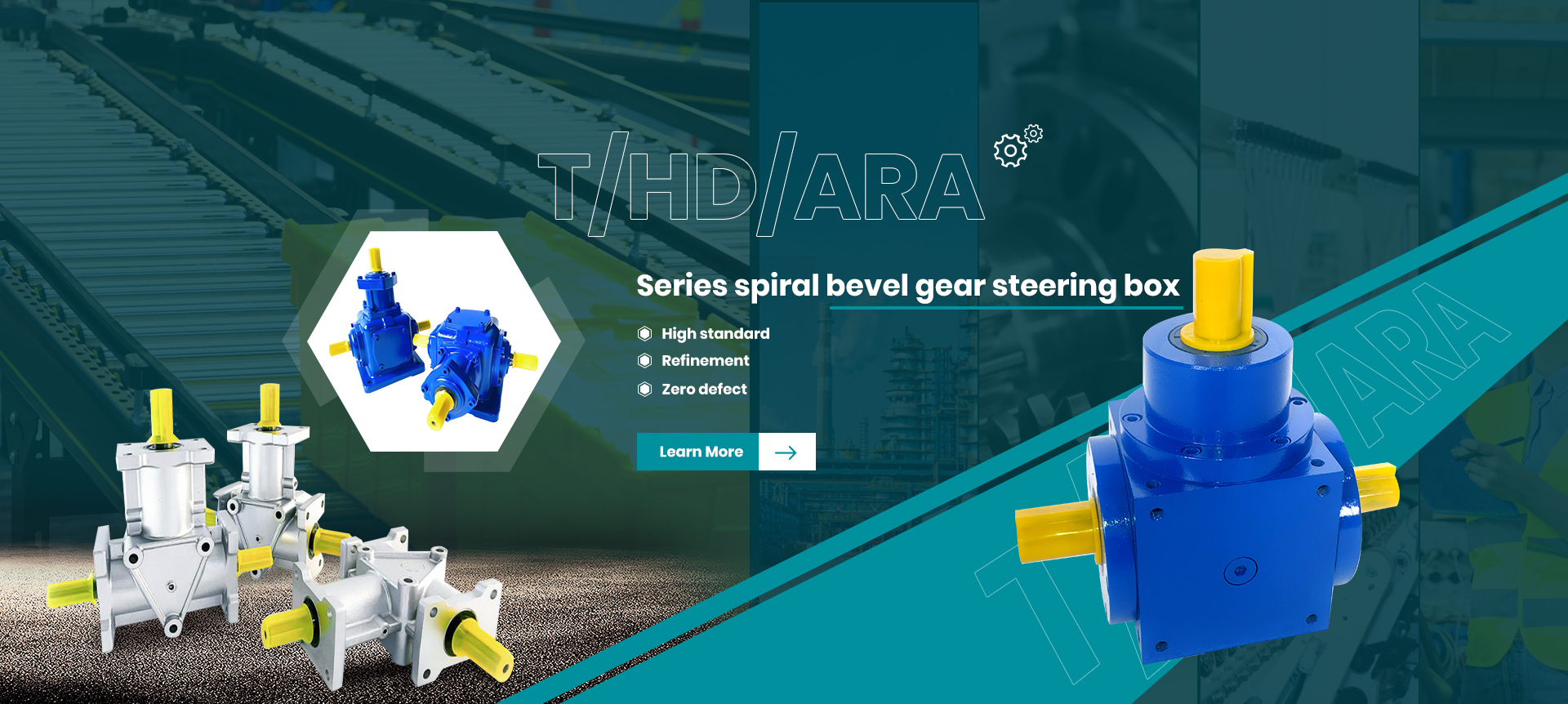

DC brushless electric roller

This type of drum motor can be installed in limited space and meet the torque requirement. Using alloy steel grinded gears and planetary transmission structure, it is reliable,free of maintenance and oil-renewing, space-saving. It can be use in many fields:

Supermarket cashier

Packaging machinery Belt conveyor

Belt conveyor lineBLD 60 Characteristics Of Drum Motor

Drum Shell

Material of standard drum shell is mild steel • Food garde shell is 304 stainless steel • Standard cylinder rolling mill gear slip flower – gear • High alloy steel precision, ensures low noise transmission when the • Planetary gear transmission -

Double Sprocket Roller with polymer bearing housing

1. Welding the steel sprocket to the steel tube gives it the capacity to transmit high torque and meet the requirements for heavy duty transportation.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water roller.

4. Temperature range: -5℃ ~ +40℃.

Humidity available ≥ 30%

Please contact us if humidity out of this scope.The roller conveyor is designed as an electric roller trough roller for continuous cargo transportation, even if it is large or heavy. Electric rollers can be galvanized, stainless steel or covered. The roller can be realized by friction roller to simplify the storage of packaging.