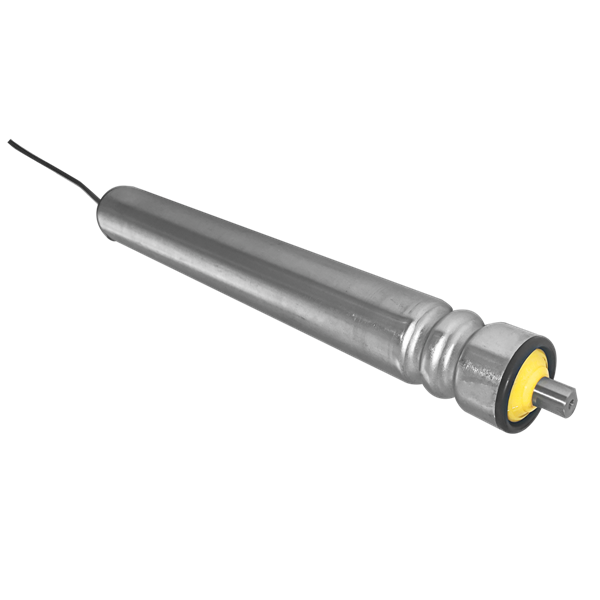

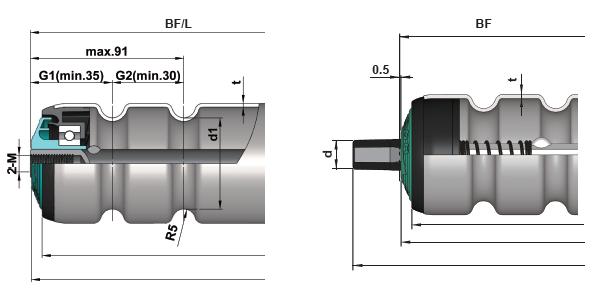

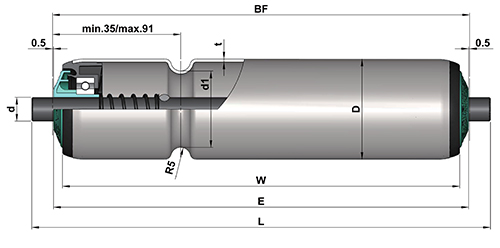

Double Grooved O-belt Conveyor

1.Simple structure, groove position customized

2.Quiet operation, Standard anti-static design

3.Application for light & middle duty

|

D |

T |

Shaft |

Tube |

|

|

Steel Z/P |

SS |

|||

|

Φ48.6 |

1.5 |

11hex,Φ10/12/14/15 |

√ |

√ |

|

Φ50 |

1.5 |

11hex,Φ8/10/12/14/15 |

√ |

√ |

|

Φ60 |

2.0 |

11hex,Φ10/12/14/15 |

√ |

√

|

Remark: Φ50 rollers can be fitted with PU sleeve (2mm).

Φ50、60 rollers can be fitted with PVC sleeve (2mm).

11hex can provide tapered plastic steel shaft sleeve roller.

Driven conveying transports goods steadily, reliably and with accurate speed. According to the driving method, it may be classified as "belt driven conveying" or "chian driven conveying".

Belt driven:

Reliable, low noise, low environmental pollution, able to run at high speed. Oily working conditions should be avoided.

Chain driven:

High load capacity. Suitable for a wide range of working environments including oil, water and high temperature however the chain is easily worn in a dusty environment. The conveying speed should not exceed 30m/min.

Electric roller is the next generation of electric roller conveyor system. General conveyor systems use efficient large motors that operate continuously and supply power to longer conveyors. Transport products to smaller areas.

"Our system provides our customers with the required functions and efficiency and reduces maintenance time. The actuator sensor interface is an open industrial network solution that reduces wiring complexity and increases control functions, which is the ideal solution for such roller conveyor systems. Belt conveyors are material handling systems that use continuous belts to transport products or materials.

The belt extends between the two end pulleys. Usually, one or both ends include a roll below. The conveyor belt is firmly supported by steel sliding discs to bear light load without friction on the conveyor belt to trigger resistance or friction on rollers. The power is provided by an electric motor using variable speed or continuous reduction gears.

The belt itself can be made of a variety of materials and should meet the belt operating conditions. Common conveyor belt elements include rubber, plastic, leather, fabric and metal. Transporting heavy objects means that thicker and stronger conveyor belt materials are required. Belt conveyors are usually powered and can run at different speeds according to the expected throughput. The conveyor can be operated horizontally or tilted.