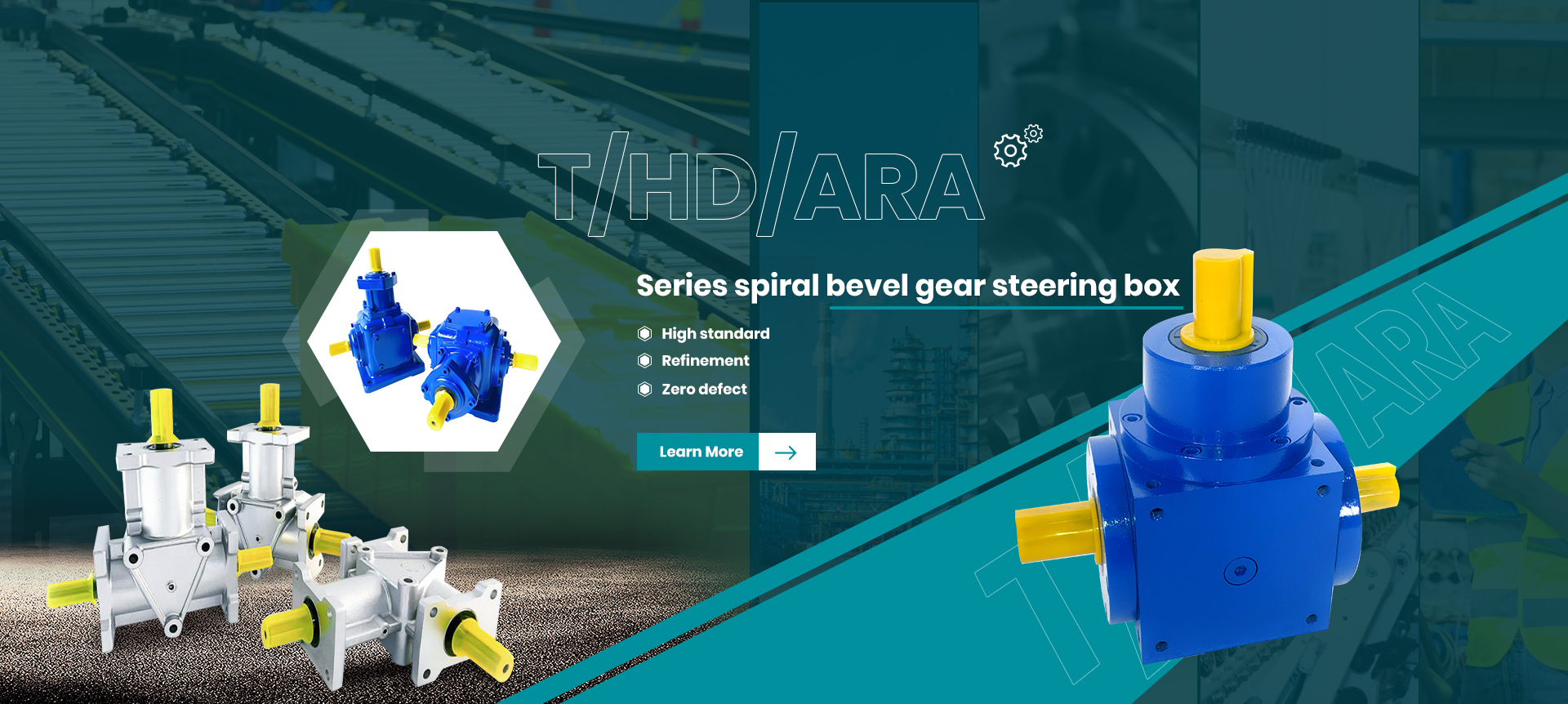

Product structure:

1. Casing: made of high rigidity fc-25 cast iron;

2. Gear: it is made of high purity alloy steel 50crmnt by quenching and tempering, carburizing, quenching and grinding;

3. Main shaft: high purity alloy steel 40Cr quenched and tempered, with high suspension load capacity.

4. Bearing: equipped with tapered roller bearing with heavy load capacity;

5. Oil seal: imported double lip oil seal is adopted, which has the ability of dust prevention and oil leakage prevention.

Performance characteristics:

1. T series spiral bevel gear steering box, standardized, multi variety, all speed ratios are actual transmission ratios, and the average efficiency is 98%.

2. The spiral bevel gear steering box is available with single shaft, double horizontal shaft, single longitudinal shaft and double longitudinal shaft.

3. The gear steering box can run forward and backward, with stable low-speed or high-speed transmission, low noise, small vibration and large bearing capacity.

4. When the speed ratio is not 1:1, the horizontal axis input and vertical axis output are deceleration, and the vertical axis input and horizontal axis output are acceleration.

Technical parameters:

Speed ratio range: 1:1 1.5:1 2:1 2.5:1 3:1 4:1 5:1

Torque range: 11.2-5713 NM

Power range: 0.014-335 kw

Precautions before installation:

1. Before using the steering box, the installation shaft shall be cleaned, and the installation shaft shall be checked for bruises and dirt. If so, it shall be completely removed.

2. The service temperature of the steering box is 0 ~ 40 ℃.

3. Check whether the fit size of the hole connected with the steering box meets the requirements, and the tolerance of the hole should be H7.

4. Before use, replace the plug at the high position with the exhaust plug to ensure that the gas in the steering box is discharged during operation.

Installation and maintenance:

1. The steering box can only be installed on the flat, shock-absorbing and torsion resistant support structure.

2. In any case, it is not allowed to hammer the pulley, coupling, pinion or sprocket into the output shaft, which will damage the bearing and shaft.

3. Check whether the steering box is flexible after installation. For formal use, please conduct no-load test, and then gradually load and operate under normal operation.

4. The steering box shall not be used beyond the rated load.

5. Check whether the oil level and the steering box are normal before use.

Lubrication:

1. The initial use period is two weeks or 100-200 hours, which is the initial friction period. There may be a little metal friction powder particles between them. Please be sure to clean the interior and replace it with new lubricating oil.

2. For long-term use, replace the lubricating oil every six months to one year or 1000-2000 hours.

3. The steering gear oil shall be 90-120 degrees of PetroChina gear oil. Under the conditions of low speed and light load, it is recommended to use 90 degrees of gear oil. Under the conditions of heavy load and high temperature, it is recommended to use 120 degrees of gear oil.

Steering box, also known as commutator and steering gear, is a power transmission mechanism and a series of reducers, which is widely used in the industrial field. At present, the steering box has realized standardization and specification diversification. The steering box has single axle, double horizontal axle and single longitudinal axle, and double longitudinal axle is optional. The actual transmission ratio is 1:1:5 and 1:1:2:1:5. The steering box can run forward and backward, and the low-speed or high-speed transmission is stable. When the speed ratio of the steering box is not 1:1, the horizontal axis input and vertical axis output are deceleration, and the vertical axis input and horizontal axis output are acceleration.

Post time: Apr-13-2022