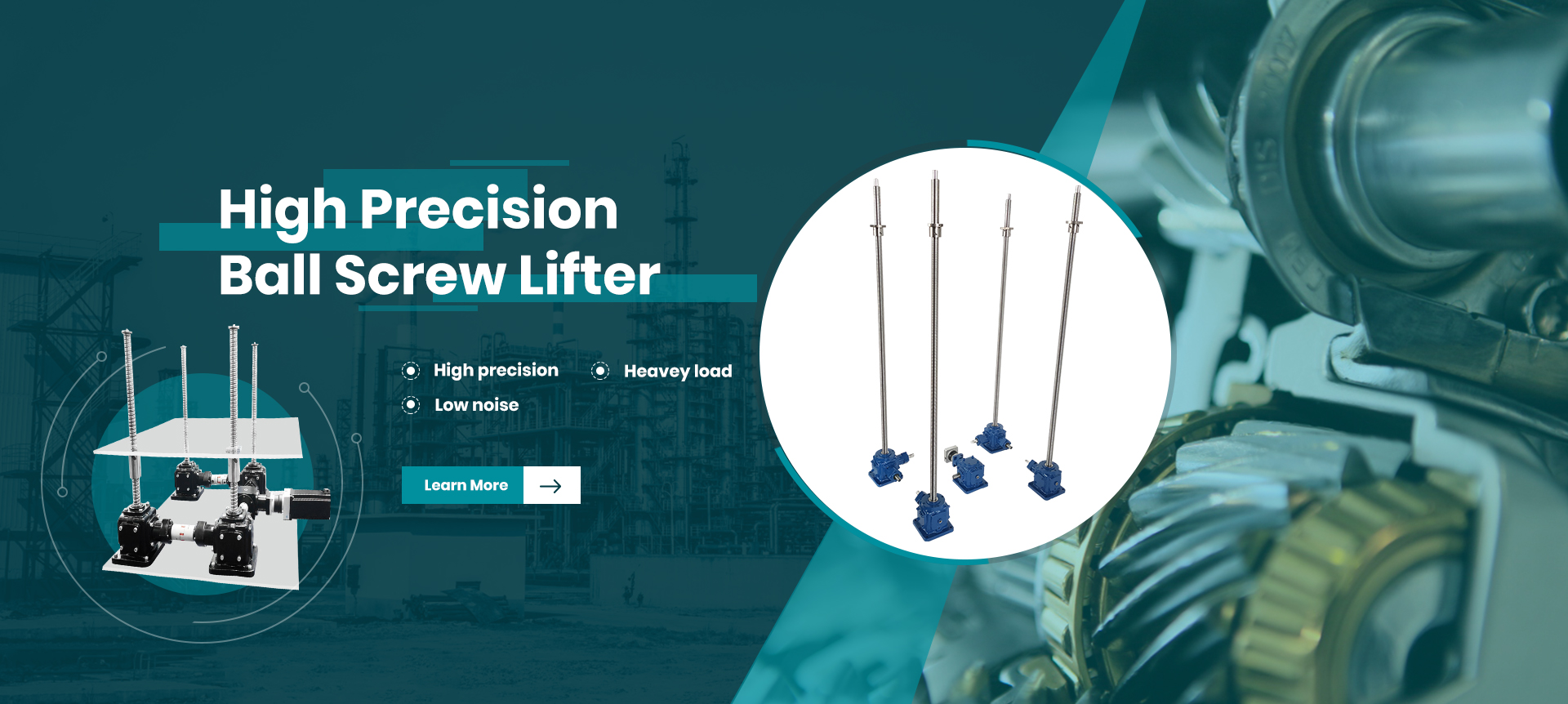

China High Quality Worm Screw Lift Factories – Screw elevator linkage platform – YEXIN

China High Quality Worm Screw Lift Factories – Screw elevator linkage platform – YEXIN Detail:

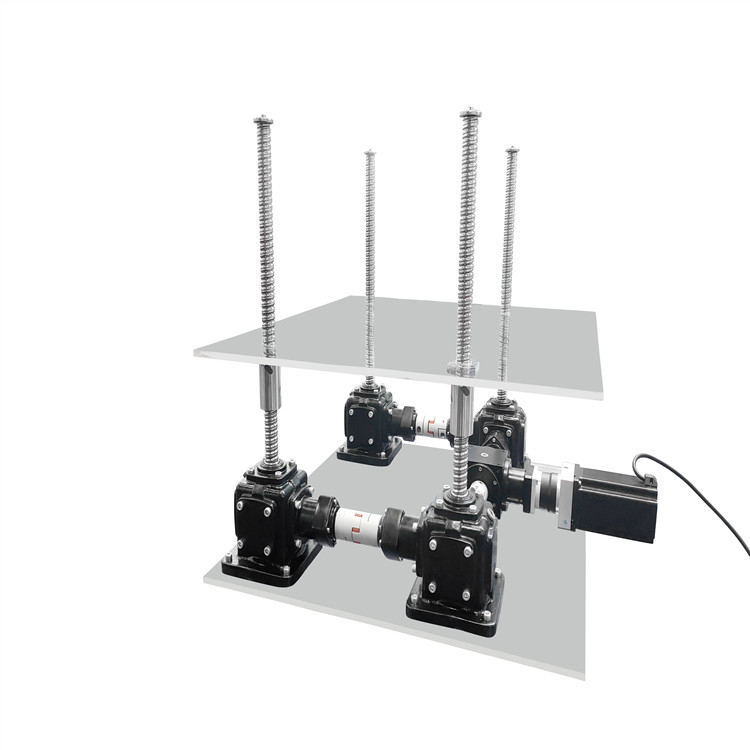

1. Lifting, displacement, tightening, turnover and other actuators in the production line;

2. Devices and tightening, lifting and turnover devices in metallurgical equipment;

3. Vehicle lifting machine, flexible tooling and welding elevator for vehicle manufacturing;

4. Lifting device and solar power generation tracking device of monocrystalline silicon and polycrystalline silicon furnace in photovoltaic industry;

5. Aerospace, national defense and military, astronomical telescope and other remote control execution devices;

6. lifting device of lifting stage;

7. Shipbuilding, water conservancy, papermaking, food, warehousing, casting and other industries; Various actuators of medical instruments, woodworking machinery and food machinery

8. Lifting devices on machine tools such as vertical lathe and gantry.

1. Good rigidity, accurate positioning and self-locking after power failure;

2. The system structure is simple and compact, and there are no complicated pump valves, oil tanks, air sources and pipeline systems;

3. Low noise, no fluid leakage and little environmental pollution. It is an ideal green environmental protection product;

4. Due to the reducer mechanism, the system section realizes a small driving source to transmit a large torque;

5. The worm screw elevator has the characteristics of precise machinery, compact design, durability, less maintenance time and long service life. In addition, without other mechanical devices, some linear or rotary motion can be realized by relying on clutch, shaft and motor and relatively simple driving scheme;

6. It can form a closed-loop servo control system to realize automatic control;

7. Use the standard original, which is easy to assemble and saves time and labor;

8. The installation is simpler and the operation time can be longer. Due to the more efficient heat dissipation, the lubrication cycle is prolonged.

★ if you need to customize the transmission scheme, product specific parameters and overall dimensions, please contact the sales engineer

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for China High Quality Worm Screw Lift Factories – Screw elevator linkage platform – YEXIN , The product will supply to all over the world, such as: Morocco, The Swiss, UAE, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!