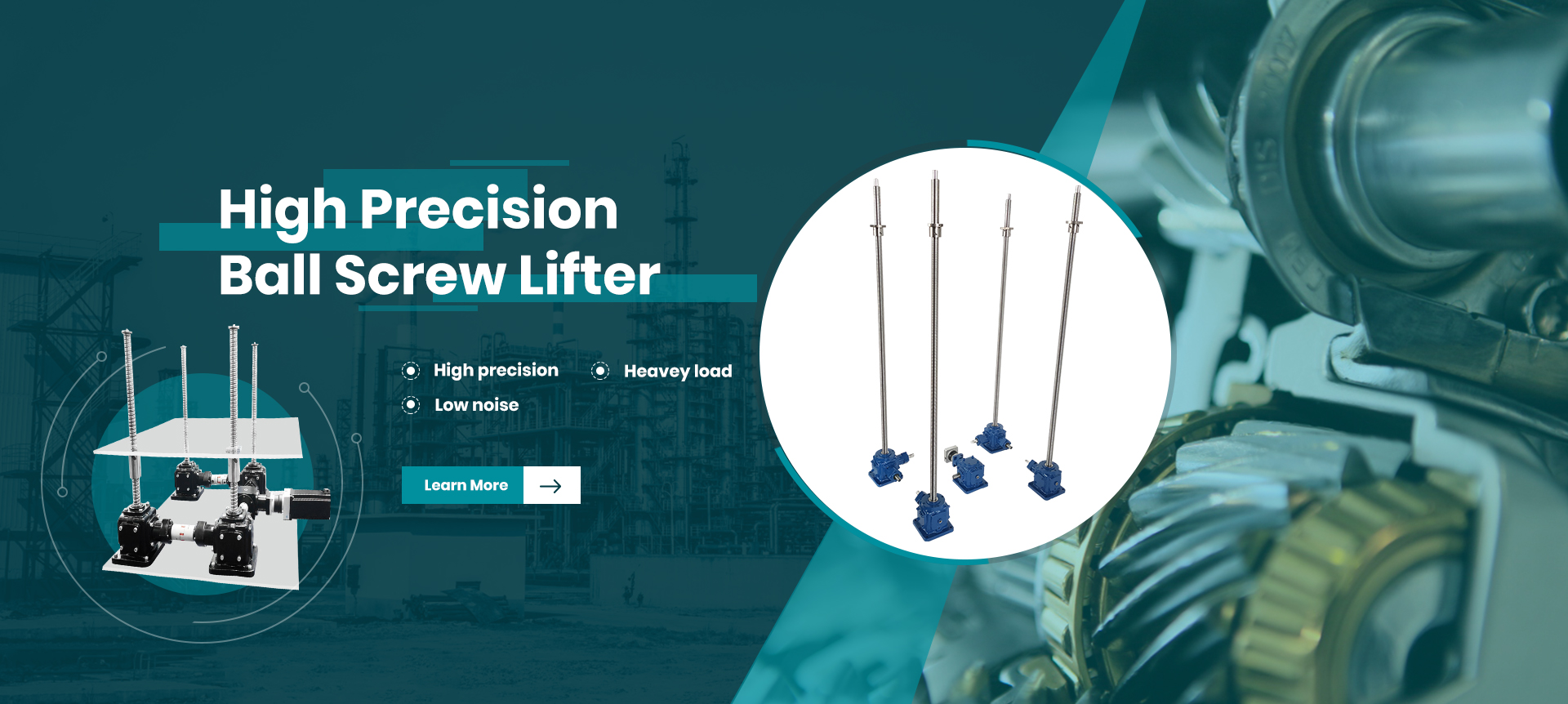

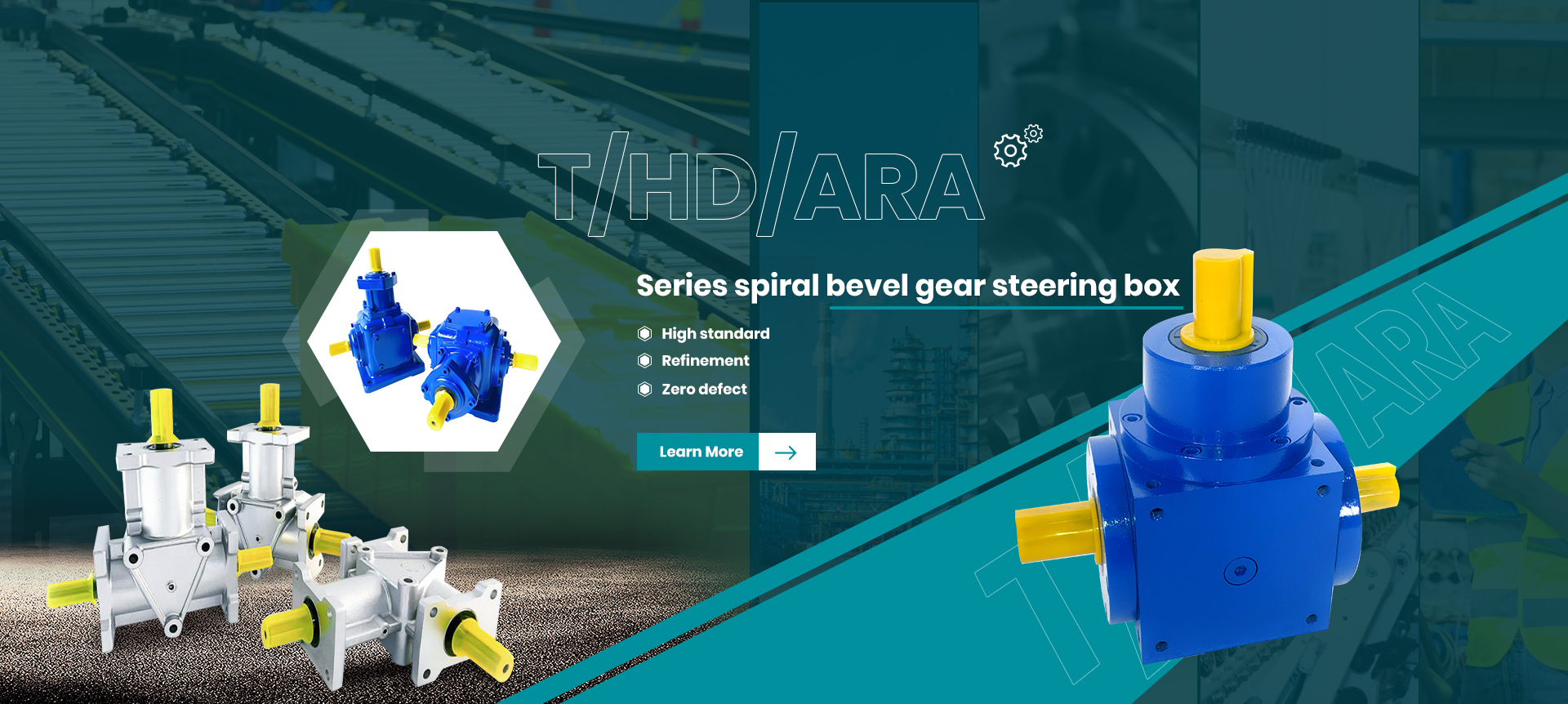

China High Quality Dc Brushless Electric Roller Factories – Double Sprocket Roller with polymer bearing housing – YEXIN

China High Quality Dc Brushless Electric Roller Factories – Double Sprocket Roller with polymer bearing housing – YEXIN Detail:

Conventional conveyors are in operation, whether or not they accumulate product. One of the major aspects of the electric drive roll (MDR) is that the MDR area operates when needed by adopting an appropriate control system strategy. In a typical MDR system, the rollers in many given areas run 10% to 50% of the running time. Energy saving can save 30% to 70%, which means that your enterprise can get faster.

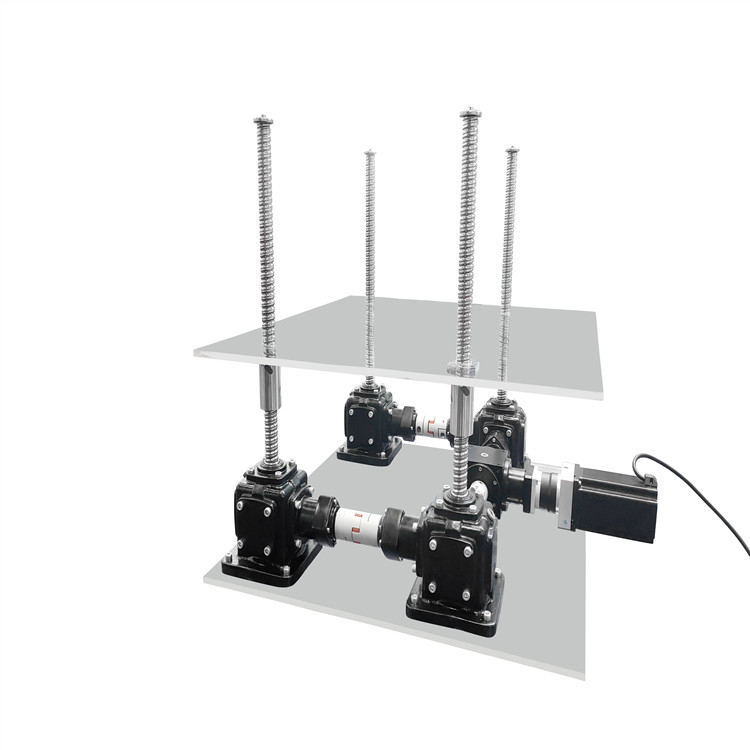

What are the advantages of the design of electric driven roller conveyor? Inherent advantages mean that your maintenance and spare parts costs are greatly reduced. Parts do not need mechanical accumulation, no maintenance for 10 years, no maintenance, zero pressure accumulation, on-demand operation characteristics, variable fixed speed regulation and reversibility, no mechanical oil gearbox and no leakage. Most conveyor manufacturers use one or more forms of electrically driven roller conveyor concept. With the passage of time, electric drive roller products have been put on the market to solve the traditional material handling function, not just zero pressure accumulation.

Several versions are merged and transferred in the market. The electric drive roller (MDR) is a conveyor roller with its own inner motor. Each motor roller controls a small range of free rotation rollers. This inherent modular design makes the design and construction of zero pressure accumulation conveyor system faster and easier than conventional conveyor system. With the change of business demand, the electric drum transmission system is also easy to replace and expand.

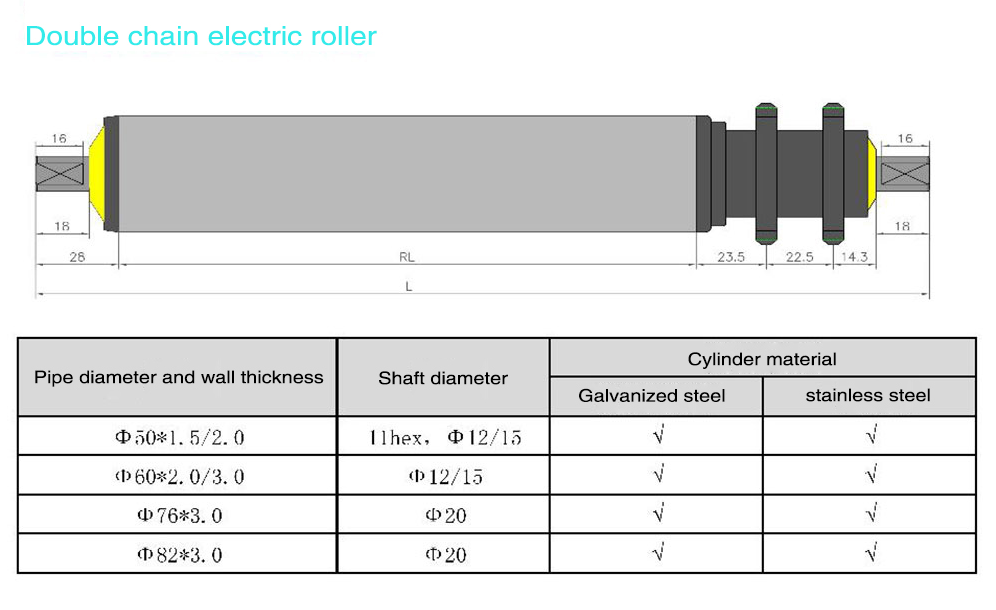

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China High Quality Dc Brushless Electric Roller Factories – Double Sprocket Roller with polymer bearing housing – YEXIN , The product will supply to all over the world, such as: Turkey, Nepal, Somalia, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!