Products

-

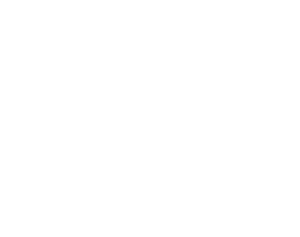

FFA Series Ball screw

Casing: high rigidity fc-25 cast iron casting; Gear: the gear is made of high-quality and high-purity diamond 20CrMnTiH carburizing, quenching and grinding; Main shaft: the shaft adopts combined diamond conditioning and high suspended load capacity; Bearing: tapered roller bearing with heavy load capacity; Oil seal: the oil seal with double sealing lips has the ability of dust prevention and oil leakage prevention; Lubrication: the use of proper lubricating oil can give play to the efficiency... -

FFNI Series Ball screw

Casing: high rigidity fc-25 cast iron casting; Gear: the gear is made of high-quality and high-purity diamond 20CrMnTiH carburizing, quenching and grinding; Main shaft: the shaft adopts combined diamond conditioning and high suspended load capacity; Bearing: tapered roller bearing with heavy load capacity; Oil seal: the oil seal with double sealing lips has the ability of dust prevention and oil leakage prevention; Lubrication: the use of proper lubricating oil can give play to the efficiency... -

FFNU Series Ball screw

Casing: high rigidity fc-25 cast iron casting; Gear: the gear is made of high-quality and high-purity diamond 20CrMnTiH carburizing, quenching and grinding; Main shaft: the shaft adopts combined diamond conditioning and high suspended load capacity; Bearing: tapered roller bearing with heavy load capacity; Oil seal: the oil seal with double sealing lips has the ability of dust prevention and oil leakage prevention; Lubrication: the use of proper lubricating oil can give play to the efficiency... -

KM series Hypoid gear reducer

KM series hypoid gear reducer is a new generation of practical products independently developed by our company. It integrates advanced technologies at home and abroad and has the following main characteristics:

1. Hypoid gear transmission is adopted, with large transmission ratio

2. Large output torque, high transmission efficiency, energy saving and environmental protection

3. High quality aluminum alloy casting, light weight, no rust

4. Stable transmission and low noise, suitable for long-term continuous work in harsh environment

5. Beautiful and durable, small volume

6. It can be installed in all directions, widely used and easy to use

7. The installation dimensions of KM series reducer are fully compatible with nmrw series worm gear reducer

8. Modular combination, which can be combined in various forms to meet the needs of various transmission conditions -

Mb Continuously Variable Transmission

Structure and working principle

1. Planetary cone-disk variator (see the drawing)

Both solar-wheel with a conicity(10) and press-plate (11) are jammed by a group of butterfly springs (12) and the input shaft (24) is linked with the sloar-wheel by a key to form a jammed input device. A group of planetary wheels with a conicity (7), with their inner side clamped in between the jammed solar-wheel and the pres-plate and outer side between the fixed ring with a conicity (9) and the speed-regulating cam (6), when the input device turms, roll purely along with the fixed ring due to both fixed ring and speed regulating cam fixed without motion and make revolution round the input shaft to drive both planetary rack (2) and output shaft (1) to run via the planetary-wheel shaft and the slide-block bearing (5). To regulate the speed, turn the handwheel, which drives the speed regulating screw to have the surface cam relatively run to produce axial displacement and thus to evenly change the space between the speed regulating cam and the fixed ring and, finally, change the working radius at the frictional place of the cam between the planetqry-wheel and the solar-wheel and between the press-rack and the fixed ring to realize the stepless speed variation. -

WB Series of micro cycloidal speed reducer

Product overview:

WB series reducer is a kind of machinery that decelerates according to the principle of planetary transmission with small tooth difference and cycloid needle tooth meshing. The machine is divided into horizontal, vertical, double shaft and direct connection. It is a general equipment in metallurgy, mining, construction, chemical industry, textile, light industry and other industries.

-

CV CH precision gear motor reducer

Performance characteristics:

1. Output speed: 460 R / min ~ 460 R / min

2. Output torque: up to 1500N m

3. Motor power: 0.075kw ~ 3.7KW

4. Installation form: h-foot type, v-flange type -

P series high precision planetary reducer

P series high-precision planetary reducer, servo planetary reducer is another name for planetary reducer in the industry. Its main transmission structure is: planetary gear, sun gear and inner ring gear. Compared with other reducers, the servo planetary reducer has the characteristics of high rigidity, high precision (within 1 point in a single stage), high transmission efficiency (97% – 98% in a single stage), high torque / volume ratio, lifelong maintenance free, etc. Most of them are installed on stepping motor and servo motor to reduce speed, increase torque and match inertia. For structural reasons, the minimum single-stage deceleration is 3 and the maximum is generally no more than 10

-

BLD DC brushless electric roller

This type of drum motor can be installed in limited space and meet the torque requirement. Using alloy steel grinded gears and planetary transmission structure, it is reliable,free of maintenance and oil-renewing, space-saving. It can be use in many fields:

Supermarket cashier

Packaging machinery Belt conveyor

Belt conveyor lineBL50 Characteristics Of Drum Motor

Drum Shell

Material of standard drum shell is mild steel • Food garde shell is 304 stainless steel • Standard cylinder rolling mill gear slip flower – gear • High alloy steel precision, ensures low noise transmission when the • Planetary gear transmission -

Double Groove O-belt Pulley Roller

1. The O-belt pulley is located the end of the roller which separates the drive area and the conveying area avoiding interference between the O-belt and the conveyed goods.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. Because there is no grooving of the tube, the tube will not have any distortion and the roller will run more smoothly.

5. Standard configuration with anti-static design surface impedance≤106Ω。

6. Temperature range: -5℃ ~ +40℃. Please contact us if humidity out of this scope. -

Poly-vee Conveyor Roller

1. The poly-vee pulley is located at the end of the roller which separates the drive area and the conveying area making the conveying smooth, high speed and low noise.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. ISO9982 PJ series poly-vee. Total of 9 grooves at 2.34mm pitch.

5. Various PJ belt lengths available to suit different pitch of rollers.

6. Suitable for the high speed applications. Maximum speed varies with roller length and diameter. Maximum speed up to 2~3m/s.

7. Standard configuration with anti-static design surface impedance≤106Ω。

8. Temperature range: -5℃ ~ +40℃.

Please contact us if humidity out of this scope. -

Double Grooved O-belt Conveyor

1. Compared with chain drive, the O-belt drive has the advantages of low noise and high speed. It is widely used for light/medium duty carton

conveying.

2. The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller.

3. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

4. The position of the grooves can be customized.

5. Standard configuration with anti-static design surface impedance≤106Ω。

6. Temperature range: -5℃ ~ +40℃.

Please contact us if humidity out of this scope.